Most Effective Injection Mould Service in China Mold Factory

There are so far so many plastic mold manufacturers available that it is most likely for you to get confused. However, Plastic injection mold is one efficient tool that is basically used for creating the aplastic parts and also ensure that they are made with precise structure and dimension. Since plastic products are the finest chosen motion, manufacturer such as LOXIN offers you the best modern dregs and ensure that product is made as per the customer’s expectation. It thus increases the demand for the product in the market while seeing that consumer gets the most innovative yet cheap solution.

Reason of demand for Plastic Injection Molds

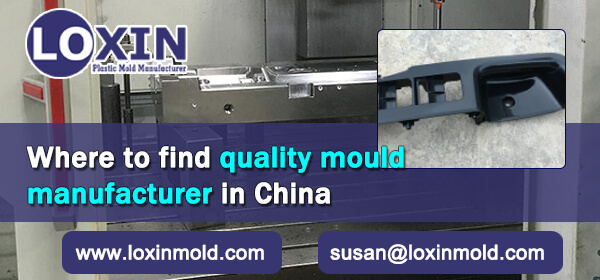

The reason why the demand for plastic injection molds especially to be made from China is more because they are not just best in quality but have the best volume solution. Talking about the price, if you compare the China injection mold with those of the Americans or Europeans at the cost friendly value. The need for technical skills is important when it comes from injection mold making project

Characteristics of a good plastic injection company

When you come across different mold maker it is quite obvious for you to get confused. But if you are looking forward to the right solution then make sure you choose a company that has an owner with a strong technical background, material procurement solution is there, and Production process is quite smooth. Besides, the quality management system at different steps of the production. Machine maintenance should also be well performed. Besides, the company, if it has a training process, will be able to replace any worker at any given time. If a company has a good plastic tool manufacturing solution, then it shall be great.

Cost Friendly Solution:

If you are looking forward to using the cost-efficient product then you shall certainly look for LOXIN. The reason why such a professional mold marker is advised is because of the qualified technicians and skilled labor team. Besides the labor cost in China is quite cost-friendly over other solutions. Other than this, you get a unique design, high-quality material and accurate designing that any other global competitor may not give.

The best part is quality is never compromised, Besides, the China mold companies only hire the technical sales who are not just good in techniques but have strong command over English too. You are not going to face any kind of difficulty whatsoever. You can stay sure of the quality and service.

The precision of mold is important to create the right functional and quality plastic product. To maintain and avail excellent practices, it is quite important to have the right type of manufacturing solution.

Options like LOXIN offers the best designing plastic solution and mold for plastic injection designs. In-country like China there are so many experts that you may come across. Since the injection molds cut down issues on mold steels and water, there is no doubt that you will ever regret choosing such a professional company for the solution that you have been looking for.

Most Effective Injection Mould Service in China Mold Factory

Most Effective Injection Mould Service in China Mold Factory 2019 Quality China Plastic Mould Manufacturer & Exporters

2019 Quality China Plastic Mould Manufacturer & Exporters

2019 Guide For Quality Injection Molding Companies

2019 Guide For Quality Injection Molding Companies

Where to find quality mould manufacturer in China

Where to find quality mould manufacturer in China

The-2019-Ultimate-Plastic-Mold-Manufacturer---LOXIN-Mold

The-2019-Ultimate-Plastic-Mold-Manufacturer---LOXIN-Mold