Prototypes are used extensively in various industries and they have a huge demand.

Prototypes are basically a sample version of a mold that become a part of a manufacturing process.

Prototypes are necessary to ensure that the overall function, fit and form.

Prototypes help in ensuring that the final molds are perfectly in line with the technical and engineering requirements as per the drawings submitted by client.

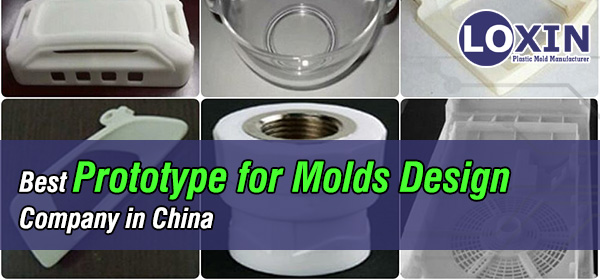

If you are on the looking for the right CNC prototype maker, then you have many reasons to know something more about us. We are known by the name Loxin Plastic Mold Manufacturer and are from China. We have our head office at Taizhou City, Huangyan District in Zheziang Province.

Though there could be many such prototype manufacturers in China, there are a few things that sets us apart from the rest of the crowd.

We are happy to share a few salient and important features and facts about us so that your search for the right China prototype maker could end here.

What Makes Us Different

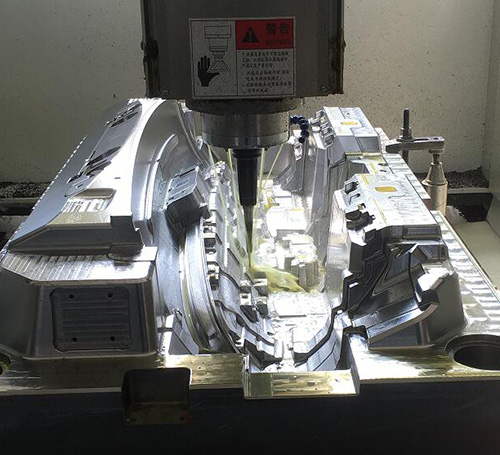

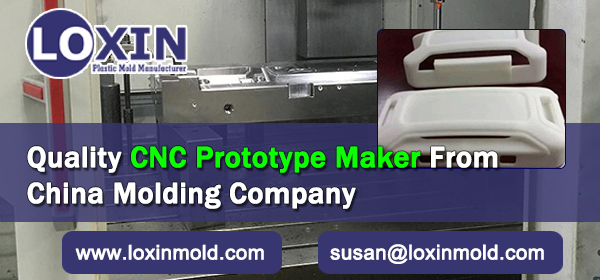

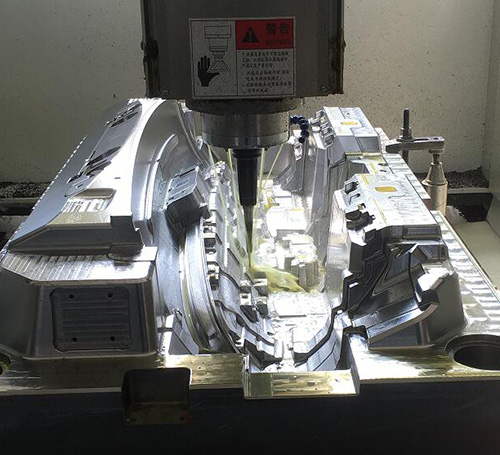

There are some obvious reasons as to why we could be considered as one of the best China mould company. First and foremost, we serve all requirements of prototype moulds for the automotive, home appliances and various other important and vital sectors. We do not just offer a stop-gap or superfluous solution out of the hat. We believe in sitting with our clients and understanding their requirements totally and fully. Hence, we are often considered to be the one-stop solution for prototype moulds for the above industries and customers.

Our project team and engineers get into the entire project from the initial stages. We sit with the customers and get into the development and tool design amongst other things. We also help in fabrication and parts production. We have separate teams for project management, design engineering, manufacturing and testing.

Therefore, you can be sure that each and every aspect of mould making including injection molding is taken care of from start to end. The customers have reposed their faith and confidence on us because we believe in adhering to the best standards of the entire process. This makes it possible for us to.

We Can Meet Any Type Of Requirement

Many customers choose Loxin because of a few more reasons. We are one of the few prototype mold makers in the country who can cater to all types of customers. It could be single part, multi-year contract requirements or a small run. We believe in offering the same kind of focus and concentration. Our attention to basic details is also something that sets us apart from many other big names in the prototype molding in China.

Experience And Expertise

We have been in operation for almost 15 years now. Hence, it would be not out of place to mention here that we have the required knowledge in production of different types of molds that meet specific needs and requirements of our customers and clients. We have experience in transacting and satisfying the requirements of various types of customers even in many European countries. Almost all of them have given a positive feedback as far as our services are concerned. We are ready to provide references of these customers so that you can know more about our experience and other credentials.

Affordability Is A Factor

We are able to maintain the right balance between costing and quality. This is because we at Loxin Mold, believe in the philosophy of manufacturing everything within the company. We do not believe in third party manufacturing. While this ensures maintenance of quality, we also can put in place the best of cost-saving devices under our watch on a 24-hour basis. While this could help in better quality, it also leads to cutting down on avoidable manufacturing costs. The benefits of the same are passed on to our customers. The customers therefore will be able to get the products from us at a much lower rate when compared to many of our competitors.

Quality Services

We also would like to mention that all our engineers are extremely skilled. Therefore you can be sure that they will be in a position to offer the high quality after sales services. We take care of making the prototypes exactly as per the requirements of our clients. However, once the orders have been executed, we also take care of the after sales services. We send our engineers to check that the prototypes are working fi9ne and are exactly as per the standards and specifications that we have contracted with our customers. This ensures almost zero defects and if there are any such issues, we take steps to have them rectified within the shortest period of time.

We have a direct channel of communication with our customers once the sales have been completed. Our specially trained managers and other technical staff will be directly in contact with our clients and take care of any issues that might arise. We do not believe in intermediaries and this goes a long way in understanding the needs and requirements of our clients much better.

We believe in direct communication with our customers even if our clients are located in far-off places like Europe and the USA. If needed, we are ready to make visits to our clients located in Europe, USA and other countries and attend to their problems directly instead of trying and sorting out the issues with the help of intermediaries.

We Can Handle Big Capacities

Our factories are quite big and have the required capacities and manpower to handle different types of prototype making. It could be small quantities as a single order. On the other hand, we also can offer regular and periodical contracts that could be on monthly, quarterly or half-yearly basis. Finally, it would also be pertinent to mention that we are capable of offering our entire factory to a single client should the capacities be big in real sense of the term.

The Final Word

To sum up, if you are on the lookout for a result oriented, proven, time-tested and cost effective prototype mold makers, you are in the right place. Please place a call to Loxin and our representative will be there to take things forward. They will understand your specific requirements and will be able to customize the same. We also offer warranty and guarantee for our prototypes as far as material, specifications, and workmanship are concerned. Hence, you can be sure that you will be in a position to get the best value for money, if you decide to choose us.

Related Prototype News

Prototypes are used extensively in various industries and they…

Best-Prototype-about-Vacuum-Form-Molds-Manufactures-in-China-LOXIN-Mold

https://www.loxinmold.com/wp-content/uploads/2019/07/Best-Prototype-about-Vacuum-Form-Molds-Manufactures-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-07-09 21:00:412019-07-09 21:00:41Best Prototype about Vacuum Form Molds Manufactures in China

Best-Prototype-about-Vacuum-Form-Molds-Manufactures-in-China-LOXIN-Mold

https://www.loxinmold.com/wp-content/uploads/2019/07/Best-Prototype-about-Vacuum-Form-Molds-Manufactures-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-07-09 21:00:412019-07-09 21:00:41Best Prototype about Vacuum Form Molds Manufactures in China Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company

https://www.loxinmold.com/wp-content/uploads/2019/06/Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-06-16 22:57:142019-06-16 22:57:14Best China Rapid Prototyping Service for Your 3D Printing Market

Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company

https://www.loxinmold.com/wp-content/uploads/2019/06/Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-06-16 22:57:142019-06-16 22:57:14Best China Rapid Prototyping Service for Your 3D Printing Market LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/Must-know-Rapid-Prototyping-Manufacture-Suppliers-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-18 17:10:212019-05-18 17:10:21Must-know Rapid Prototyping Manufacture & Suppliers in China

LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/Must-know-Rapid-Prototyping-Manufacture-Suppliers-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-18 17:10:212019-05-18 17:10:21Must-know Rapid Prototyping Manufacture & Suppliers in China LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/3D-Printing-Parts-from-High-Quality-China-Molding-Company-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-18 17:02:032019-05-18 17:02:033D Printing Parts from High Quality China Molding Company

LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/3D-Printing-Parts-from-High-Quality-China-Molding-Company-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-18 17:02:032019-05-18 17:02:033D Printing Parts from High Quality China Molding Company LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/How-to-Find-the-Reliable-Customized-Plastic-Injection-Mold-Manufacture-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-17 16:45:342019-10-28 10:21:31How to Find the Reliable Customized Plastic Injection Mold Manufacture

LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/How-to-Find-the-Reliable-Customized-Plastic-Injection-Mold-Manufacture-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-17 16:45:342019-10-28 10:21:31How to Find the Reliable Customized Plastic Injection Mold Manufacture LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/How-to-get-best-Prototype-Mold-Suppliers-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-17 16:36:352019-05-17 16:36:35How to get best Prototype Mold Suppliers in China

LOXIN Mold

https://www.loxinmold.com/wp-content/uploads/2019/05/How-to-get-best-Prototype-Mold-Suppliers-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-05-17 16:36:352019-05-17 16:36:35How to get best Prototype Mold Suppliers in China https://www.loxinmold.com/wp-content/uploads/2019/03/Best-Prototype-for-Molds-Design-Company-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-03-01 10:51:022019-03-01 11:12:47Best Prototype for Molds Design Company in China

https://www.loxinmold.com/wp-content/uploads/2019/03/Best-Prototype-for-Molds-Design-Company-in-China-LOXIN-Mold.jpg

280

600

luxinadmin

https://www.loxinmold.com/wp-content/uploads/2022/04/YL-LONG-logo.png

luxinadmin2019-03-01 10:51:022019-03-01 11:12:47Best Prototype for Molds Design Company in China

Best-Prototype-about-Vacuum-Form-Molds-Manufactures-in-China-LOXIN-Mold

Best-Prototype-about-Vacuum-Form-Molds-Manufactures-in-China-LOXIN-Mold Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company

Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company LOXIN Mold

LOXIN Mold LOXIN Mold

LOXIN Mold LOXIN Mold

LOXIN Mold LOXIN Mold

LOXIN Mold