China Plastic Mold Manufacturer & Injection Molding Supplier

What is a plastic mold injection? Why do you need to hire the best plastic mold manufacturer to get a quality product? What are the ways to choose the best China plastic manufacturer? If you are interested in plastic molding products and looking for a reliable name in the industry, you can go through the following article. It will educate you about the plastic mold injection, and then it will introduce an experienced and reliable molding supplier.

WHAT IS PLASTIC MOLD INJECTION?

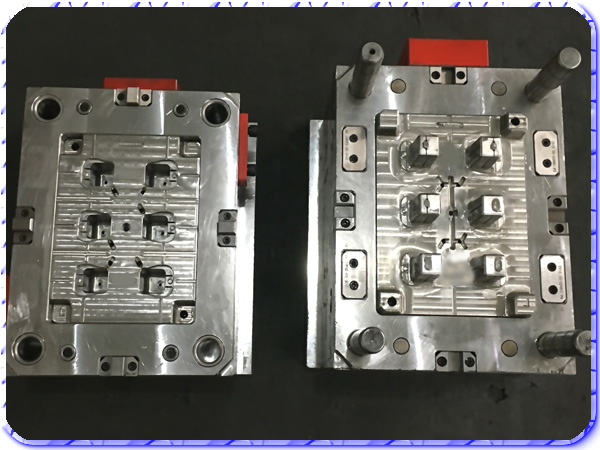

Plastic mold injection is a manufacturing process. This method is used for manufacturing different plastic parts including small and large parts. An injection molding machine is used to melt the plastic and then it is injected into the mold so that it will cool down and solidify into a product. The plastic mold injecting is used to manufacture a wide range of plastic products that include airplane components, automotive parts, musical instruments, storage containers, and combs. However, you will have to choose a reliable plastic mold manufacturer to get the unique injection mould design and fast delivery. If you are looking for such a name, you can consider LOXIN, one of the most reliable mold suppliers in China. Let’s know more about this manufacturer to make an informed decision.

- LOXIN: THE PLASTIC MOLD MANUFACTURER

LOXIN is a popular name across China due to fast solutions and quality products. They can offer you a wide range of plastic molding solutions. You can invest in this manufacturer to meet most of your plastic molding needs that range from home appliances to automotive parts. Their experienced team will help you throughout the process to get a unique tool design. They offer a wide range of services that include professional engineering, project management, and manufacturing. Their quality and versatility make them lead the industry.

Even if you have a small project, you can expect the best outcome. They deal with every project with utmost care regardless of the size. They will focus on every detailing so that you can expect a good combination of quality and durability. Their key objective is to win your satisfaction.

WHEN SHOULD YOU CONTACT LOXIN?

You can consider this experienced manufacturer for all types of plastic molding. They have around one and a half decades of experience in the industry. They understand each project and its unique requirements. Their skilled team can design a solution regardless of the complexity of the project. You can expect genuine and quality products at a less expensive price. The solutions will be fast as well.

Also, the company does not take the help of the middlemen to supply products. The products will be supplied directly from the manufacturer. Therefore, you can expect genuine and quality products. As there will be no middlemen, you can expect the best price.

In addition to the above, you can get the best mold designs and manufacturing. They have the skill and experience to exceed the industry standard. They have succeeded to create their specific brand identity. They will try their best to create a customized solution depending on your unique needs. You can reach out to them to discuss your project.

BENEFITS OF HIRING LOXIN

There are many benefits. First of all, you can expect quality products. The quality will be unparalleled without charging more. Yes, you can expect cost-effective solutions. The best quality and durable product will be supplied at your doorstep without affecting your budget. If you compare other products with the LOXIN, you will certainly find LOXIN worth spending.

They handle all the projects. Even if you have small projects and you are looking for customized solutions, you can hire LOXIN. Needless to mention, the quality will not be compromised. Their experts will go through the details to ensure that all the products meet the industry standards even if it is a small project. You can order once and develop a long-term commitment with the manufacturer to get all the required help whenever needed.

The team members are well-trained and thoroughly professional. They will answer your queries and will help you with the best possible solution. You just need to share your unique requirements. They will take care of the rest. You can inquire about the team, process, as well as machines. They will get back to you at the minimum possible time.

LOXIN's-Plastic-Mold-Increase-Your-Molding-Market

LOXIN's-Plastic-Mold-Increase-Your-Molding-Market

What-is-Plastic-Injection-Mold-Working-Process

What-is-Plastic-Injection-Mold-Working-Process How-Much-China-Plastic-Injection-Mold-Cost

How-Much-China-Plastic-Injection-Mold-Cost High-Quality-China-Injection-Mold-Manufacturing-Increasing-Your-Business-LOXIN-Mold

High-Quality-China-Injection-Mold-Manufacturing-Increasing-Your-Business-LOXIN-Mold High-Quality-Mold-Design-Engineering-Suppliers-in-China-LOXIN-MOLD

High-Quality-Mold-Design-Engineering-Suppliers-in-China-LOXIN-MOLD Plastic-Injection-Auto-Head-Lamp-Molding-Manufacturer-LOXIN-Mold

Plastic-Injection-Auto-Head-Lamp-Molding-Manufacturer-LOXIN-Mold Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company

Best-China-Rapid-Prototyping-Service-for-Your-3D-Printing-Market-LOXIN-Mold-Company